In the eyes of villagers in wujiang town, Anhui and County, Ye Lianping is a "freak".

A 90-year-old retired teacher receives 3,000 to 4,000 yuan a month. In order to save 80 cents, he often rides 7 kilometers to the town to buy vegetables, and also picks up vegetables discarded by vegetable vendors and takes them home. I don’t want to take a bus when I travel far away. I go to Nanjing, Wuhu and Yangzhou by bike, and I have been to Guannan as far as 300 kilometers.

People who live in an old bungalow 30 years ago and wear rags 60 years ago are so frugal that ordinary people can’t understand it. After retirement, they are obliged to help students with English for 19 years, without receiving a penny, but they always spend hundreds, thousands and tens of thousands of dollars on students.

Ten years ago, Wang Xiaosi, director of the party member Audio-visual Education Center of the Organization Department of the County Party Committee, was puzzled when filming Ye Lianping’s documentary. What was supporting him to do so? After three years of filming, he seems to have found the answer, but it seems that he hasn’t. Afterwards, he has been thinking about this problem.

In the face of incomprehension, Ye Lianping explained a lot of reasons on various occasions, and finally there was only an understatement: "My situation is different from that of others, and my life can be written as a book."

On May 5th, Ye Lianping was in an English class. Zhang Dao Kuan tu

A painting of the blind.

One evening in June, 1984, it was a little dark. At the age of 15, Chang Jiuming was working in the cotton field with his parents, and he saw Teacher Ye stumbling over from afar. His parents told him to hide quickly so as not to be seen by Teacher Yuzryha.

That afternoon, he told Mr. Ye not to study, and then went home early. His home is five kilometers away from the school, and the road is difficult to walk. He has to cross the river and climb the mountain. The river is on the edge of the Yangtze River, which is in the flood season. He didn’t expect teacher Ye to come.

Teacher Ye came to persuade him. He got good grades and wanted to study very much, but his family was so poor that his three sisters didn’t study. His parents had already found him a good master to learn tailoring. "Our whole family respects Mr. Ye very much, and when the teacher says that we can’t stand it," Chang Jiuming hid in the dark before he dared to go home.

There were many people who didn’t study at that time, and the teenagers couldn’t understand why the teacher came so far to persuade. After he stepped into the society and walked through many bumps, he realized, "That’s an old man’s reluctance."

Thirty-four years have passed, and Chang Jiuming still deeply remembers the picture of Teacher Ye stumbling that evening. "Every time I think about this, I have to cry." He cried when he recalled, and it took him a few minutes to calm down.

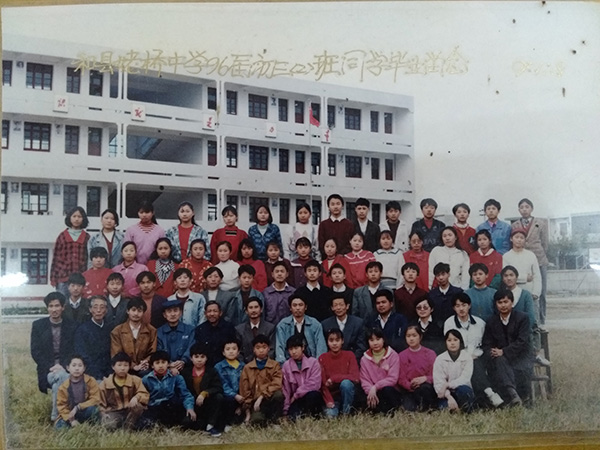

Buchen Middle School took a group photo with the graduating class of junior three in 1984. Ye Lianping was in the second row and the sixth from the right. In addition to the signature, the pictures in this article are all pictures of reporter Zhang Xiaolian.

Chang Jiuming didn’t know that many years ago, a similar scene happened to Teacher Ye.

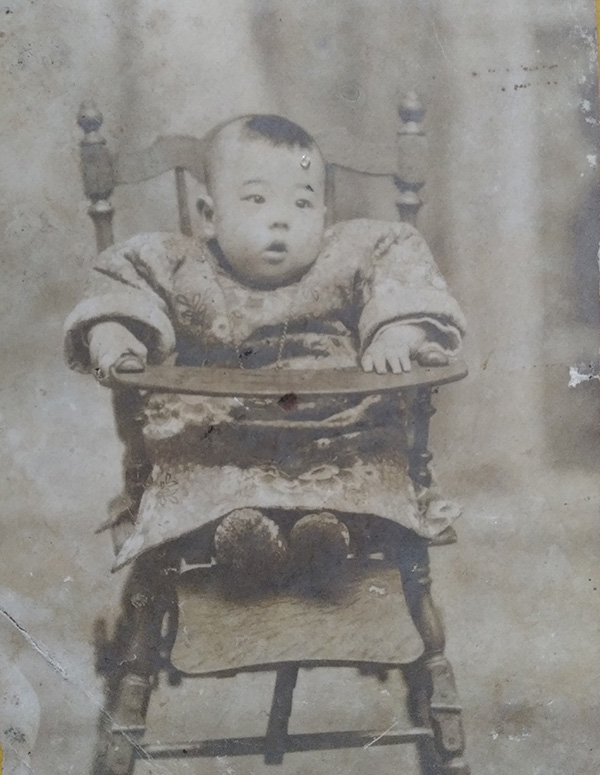

In 1928, Ye Lianping was born in Qingdao, Shandong Province, with two half-sisters above and two siblings below. He was the only child in the family and was pampered since childhood. My father works as a cook for foreigners. He often brings some tea and fruit back from work very late and stuffs them into his sleeping bed.

My father is from Cangzhou, Hebei Province. When he was young, he studied with his third brother. He didn’t bounce his legs straight, got a slap and ran to Tianjin in anger. Because there is no culture, you can only give people pages and work as coolies. My father told a true story: Man Mou, a Weifang native, was working for foreigners in Qingdao. His employer relied on him to steal his wife’s jewelry, wrote a complaint and told him to send it to the police station himself. Man Mou was illiterate and was locked up on the spot.

My father has been illiterate for more than three generations, and he has suffered a lot. Although he has problems with food and clothing, he still tries his best to make him study.

When Ye Lianping was 8 years old, his family moved to Tianjin and went to a private school. Japanese teachers taught Japanese in primary schools. At the age of 12, his mother died of illness. He followed his father and stepmother to Shanghai and entered Guangxia Middle School to study English.

Ye Lianping was a child.

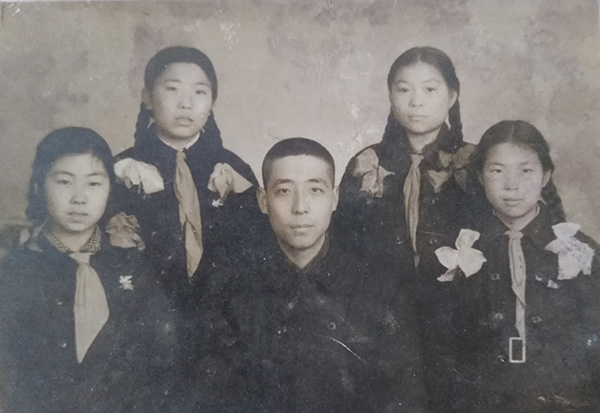

Ye Lianping took a group photo with his parents, sister and brother (who died in his early years) and it has been well preserved so far.

He doesn’t know anything about English, and he doesn’t understand Shanghai dialect. As a short man sitting in the front row, he always hears jeers coming from behind. Several tall girls stop him and call him "thirteen o’clock" in Shanghai dialect.

He couldn’t bear it anymore and told his father not to study. Father was so angry that he punched him hard in the chest. My father hit him once in his life. After the fight, I was distressed. I bought him a plaster and persuaded him softly.

Ye Lianping studied hard from then on. He has a good memory and learns things quickly. Li Bai’s Preface to the Peach and Plum Garden at the Spring Banquet can be memorized in ten minutes. I graduated from junior high school and got the first place in my class. The second one later became a professor of mathematics in Tsinghua University.

With the outbreak of the Pacific War, American employers left one after another, so my father lost his job, started to set up stalls to repair bicycles, and also trafficked rice to the suburbs by bike. He was always on tenterhooks when passing Japanese checkpoints. Once the devil stabbed the sack with a bayonet, and the rice was scattered all over the floor, so he dared not collect it.

In such difficult times, my father still insisted on providing him with education. When senior high school entered Nansu Middle School, Lin Zhichun, the head teacher, knew that he was in a difficult situation and gave him help in many ways. But after a semester, life has reached a desperate situation.

Teacher Lin heard that he was going to drop out of school and repeatedly advised him to cheer him up, but there was no way. "How can I read when I am hungry?" Teacher Lin couldn’t bear to part with it. She drew a watercolor painting and handed it to him at parting. Her eyes were full of tears.

The picture shows a blind man, leaning on a stick in one hand and playing a musical instrument in the other, exploring the way forward. This painting was burned during the Cultural Revolution.

An undressed hat

On the morning of May 5, 2018, Ye Lianping looked around in the rain, waiting for the last girl who was late. He was worried about the rain, and some children couldn’t come. I didn’t expect all 48 people to arrive.

It has been Ye Lianping’s practice for more than ten years to take students to Nanjing and Hefei and visit science and technology museums, museums and martyrs’ cemeteries, once a year in spring and autumn. Anhui Science and Technology Museum was impressed by Mr. Ye’s behavior, and began to subsidize it three years ago. In order to cover all the expenses, Ye Lianping refused and insisted on paying the fare. He paid half a month’s salary for this two-day trip to Hefei.

In the drizzle, the bus was running on the highway, and the car rang with neat songs: "XYZ,Now you see,I can say my ABC." Ye Lianping stood in the aisle and led the singer, waving his hands, with a loud voice and full of enthusiasm, just like every class he had, as if he would never get tired.

On the way to Hefei on May 5, Ye Lianping was busy in the car, giving items to the children. Zhang Dao Kuan tu

On May 5, students started to make remote-controlled cars in Anhui Science and Technology Museum to participate in the competition, and Ye Lianping watched silently.

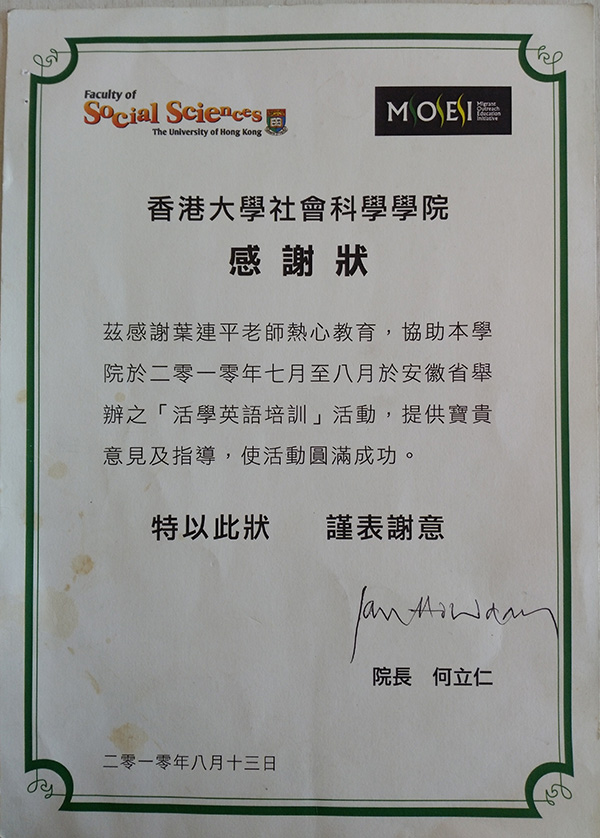

Last year, when I visited Nanjing Yuhuatai Martyrs Cemetery, I met three foreigners. The children ran to talk to them. The other party said in French, "I can’t speak English, we are the French." Ye Lianping studied a little French and Russian when he was young. However, he is best at English, and his communication is barrier-free. He once received Ian Holliday, vice president of the University of Hong Kong.

Letter of thanks from the School of Social Sciences of the University of Hong Kong to Ye Lianping.

When he dropped out of school at the age of 17, he won the Anti-Japanese War. The following year, I went to Nanjing with my father and worked in the American Embassy. At first, I didn’t know English, so I had to be a handyman.

David Berger, my father’s boss, is the first secretary and can speak Chinese. Once he called Ye Lianping and deliberately said in English: "George! A hammer,please?” Ye Lianping looked puzzled. Thanks to his good memory, he wrote this sentence down intact, ran downstairs to find Uncle Li who answered the phone and repeated it. Uncle Li told him that "hammer" was a hammer, and he quickly sent it with a hammer. Baige touched his head and praised, "Good! Good!”

From the opening to the closing of the embassy, Ye Lianping lived among foreigners for three years and six months, dealing with foreigners all day long and "practicing his mouth".

The handyman can receive anyone. Ye Lianping knew Si Tuleideng and Butterworth, met Song Ziwen, Sun Ke, Bai Chongxi, Chen Cheng and Weng Tongshu, and shook hands with Song Meiling.

During my work in the embassy, foreigners took photos of Ye Lianping.

"It was because of the embassy that I suffered a big loss." As soon as the old man talked, his eyes were wet, and two lines of muddy tears overflowed and slowly flowed down the wrinkles along the ravine. "Please forgive me. Every time I think about this, I can’t control my feelings. " He took out an old handkerchief from his pocket and wiped his eyes. "I almost gave up my life."

In the early days of liberation, many working people were illiterate. After leaving the embassy, Ye Lianping was temporarily unemployed and bored, so he joined hands with several residents and colleagues to start a literacy night school. The allowance is limited, but nobody cares.

Ye Lianping took a group photo with four female students at Nanjing Literacy Night School.

In the winter of 1955, Ye Lianping was the general manager of the mass night school in Nanjing Langya Road Primary School. One day, the household registration police suddenly came to the school and took Ye Lianping away. After more than 9 months of isolation and examination, nothing was found. He was put under control for another year, supervised by the masses, and the police often came to ask him to write information. After two and a half years of examination, I didn’t wear my hat. But in the next twenty years, I could never get rid of the suspicion of "spy".

"At that time, I was afraid to wear it. Now that I think about it, I still want to wear it. Anyway, I have been tortured. If I put on my hat and pay my salary later, I will earn it! " Ye Lianping spends $102 a month at the embassy. He could have gone to get a pension, but he was afraid to take it.

In 1960, the household registration police came to the door again, asked him to sign a volunteer letter and forced him to leave Nanjing. He was sent to his hometown Cangxian and lived in the house of three uncles. The cadres of the brigade discussed that there was a "bad boy" in the south.

It was a natural disaster for three years, and Ye Lianping couldn’t do farm work, making it worse. At first, I have some luggage, so I can take the train to Shandong to change some dried sweet potatoes and let the whole family stay for two more days. After several trips, even the shoes and towels were replaced. I’m so hungry that I eat all kinds of wild vegetables, bark and raw toads, and I have diarrhea after eating them.

When Ye Lianping was released in 1960, his brother-in-law gave him a cotton vest, which is still worn today. Sweat stains on clothes are memories of hard work.

In this way, I spent an extremely difficult three years. By 1963, my legs were swollen to my knees, and I couldn’t take off my socks. I finally gritted my teeth and returned to Nanjing.

Ye Lianping took the migration permit to settle down, but the police station refused to accept it. Without hukou, there is no salary, no food stamps, and you still don’t have enough to eat. In 1965, introduced by my colleague and lover, Director Zhang, I had to come to Shibu River.

saving his life

Shibu River, not far from Nanjing, is located in wujiang town, Anhui County, which belonged to Buchen Commune. Ye Lianping suffered the heaviest political repression and gained the most goodwill here.

Started boarding at the factory director Zhang’s house. Director Zhang’s nephew, Zhang Guangyuan, was in high school in Hexian County. He went home at the weekend and said, "Hey, why did a foreigner come to our family?" Because Ye Lianping is tall and long, with a long nose and face, and speaks Mandarin.

When the chicken was slaughtered at home, Zhang Guangyuan called him to eat it. He said that he "never ate meat, eggs or fish in his life" and was only a vegetarian. There are many leeks at home, and he likes leeks best. This state lasted for several months.

The villagers feel that "this person is a bit strange", and they don’t speak up and talk less. No matter what the score is, he does everything. "He never cares whether he remembers the score or not, and how much the score is."

First, I went to work in the kiln, burning, moving and pulling bricks, and barely worked for a year. When the director saw that he couldn’t do it, he made him a cook, carrying thirty loads of water a day, and he was very tired.

During this period, the cadres of the brigade were offended. The brigade department brought a few eels and asked him to burn them for the cadres to drink. Ye Lianping didn’t dare to touch this living creature that resembled a poisonous snake. A cadre made two horizontal remarks, which made him lose control: "I cook for the staff, not serve the cadres!"

This cadre later posted Zhang Ye Lianping’s posters. The commune informed the brigade to transfer Ye within three days, and the secretary of the brigade advised him to avoid it temporarily, and he could come back when the limelight passed. Ren Shuji squatted on the bench and said, "You are a good man!"

In 2012, Ye Lianping was named "China Good Man". He gave a speech in Hefei and talked for 45 minutes. After the lecture, a retired cadre came up and took his hand and asked, "How did you become a good person in China?" I stopped him at once, and he was "so stiff that he was almost humiliating". More than 600 people in the audience had not dispersed. When he was in a dilemma, a sentence suddenly floated out of his mind: "Because I live among good people."

The kiln colleagues gave him sweet potatoes, and the villagers took him in. He couldn’t do heavy work, so the brigade arranged for him to go to the production team. He is not good at farm work, so the production team takes care of him and lets him plant trees and raise pigs to keep score.

Ye Lianping returned to Shibu River again and was accepted at home by Zhao Xingzhu. The cadre of the brigade threatened him to drive Ye Lianping away. Zhao Bingzhi was upright and outspoken, patting his chest and saying, "I am a poor peasant in Zhao’s family for three generations. If Lao Ye breaks the law, I will take the blame!" Just protect him.

One morning, Ye Lianping was drying the harvested rape in front of the door, and the captain informed the morning meeting. On the way to the commune, the militia battalion commander Chen Chaoyu called him out of the queue and told him, "No matter what it says, don’t be silent."

At that meeting, ten people were criticized, such as fortune tellers, beggars, duck feather changers and so on. A man refused to bow his head and was thrown to the wall by the militia. It’s Ye Lianping’s turn. Angry complaints filled the whole process, and he never said a word.

"I’m so angry when I get home!" As soon as I entered the house, I burst into tears. He shrank in his room, and the more he thought about it, the more uncomfortable he became, and he died. Just then, Li Yincai across the hall pushed the door and came in, persuaded him for a long time, and helped him collect and beat rapeseed.

In 1970, in the early winter, Ye Lianping was taken to the headquarters of "Wen Attack Wu Wei" in Liyang Town, where three religions and nine streams were mixed together and closed for more than seven months. Commanders beat people when they are drunk, and girls often cry at night. Ye Lianping was slapped twice in the foul smell of alcohol.

Liu Youliang, a team member who once took him in, told his lover Zhao Guizhen to fry a bag of cooked wheat noodles and send it to the headquarters. Ye Lianping was amazed when she saw her, and almost burst into tears when she saw the bag of fried noodles again.

In that environment, no one dares to get close to him for fear of avoiding him. His wife left him and his relatives alienated him. Liu Youliang and his wife are not related to him, but they braved the heat and traveled five or six miles to send him a small bag of fried noodles.

"If it weren’t for these good people, I would have died long ago." Ye Lianping read one name after another in his mouth and said emotionally, "These people are all things I will never forget, never forget."

After bringing order out of chaos, he had two opportunities to return to Nanjing to settle down and never returned. When he became a teacher, the two directors of the Education Bureau asked him to be transferred to the county, but he also declined.

"I came here at the most difficult time. This place saved my life. The elders here need me and I can’t leave."

This old man, who was displaced and suffered a lot in the first half of his life, decided to take root in a foreign land, take out everything he had and watch the children running on this land.

"Doing nothing"

Ye Lianping has been teaching for forty years, and students are everywhere, and you can meet them everywhere.

On the morning of May 11th, he crossed the river by boat to the train station to see the shift. The only grandson of the third uncle got married in a few days. He went back to Cangzhou for a wedding banquet and refused to buy a berth ticket for more than ten hours.

When I went, a van master called him, a former student, and told him to get on the bus. He didn’t get on, probably not wanting to delay others’ time. When he came back, a student sold fish at the dock, helped him get on the boat, got off the boat, carried it down again, and gave him two fish.

The villagers near Buchen School have other students in almost every household. Retired teacher Lao Han’s son, daughter and son-in-law have all been taught by him, and his grandchildren have also made up lessons there, producing four college students. Lao Han said: "He has trained two generations in my family."

Many years ago, students made up lessons in Ye Lianping’s yard.

Ye Lianping clearly remembers the day when he stood on the podium again, November 24, 1978. Twenty-three years have passed since he was removed from night school in 1955.

These twenty-three years are the golden age of his prime. "What can I say? I’ll never come back … I’ve worked hard and I can’t make it up."

In 1978, Zhang Guangyuan was admitted to the university. At that time, he was the head teacher of Buchen Middle School’s third-year graduating class. When he left, no one took Chinese classes. He said to the school leaders, "You should emancipate your minds. I will recommend someone to you, Ye Lianping."

"People think I am the best teacher here, but in fact he can be my teacher." Zhang Guangyuan said.

Ye Lianping has been a swineherd for nearly ten years and is responsible for more than 30 pigsty of the whole team. At that time, adults, including old men and women, attended work to earn work points, leaving only dolls at home. He wandered around the team area all day, taking care of the young children. The child who is studying often comes to ask homework after school, so he is probably familiar with textbooks.

When the brigade cadres came to the pigsty to call him that day, he was hooking pig excrement, wearing rubber boots and holding a rake. He jumped out of the pigsty without any mental preparation, so he rushed to the brigade office armed and smelly. The director of Buchen Middle School sat behind the desk to test his textbook, and then made a decision to let him come to school the next day.

From a swineherd to a teacher overnight, Ye Lianping never dreamed. The commune sent people to Nanjing with the headmaster to check his files, and the conclusion he brought back was only three words: OK.

He took over Class A, Grade Three, with 48 students. Before that, he left classes for more than a month, and the composition books to be revised piled up into hills, with tight time and heavy tasks. Students live in scattered places, so it is difficult to ensure safety if they stay in school and work night shifts. So he divided the whole class into five groups, gathered students from neighboring villages together, found a suitable family to attend classes, and went to five groups in the countryside every week. Parents are very supportive, lighting two lamps. After a few months, the effect is quite good, and 11 students were admitted to the senior high school entrance examination, 9 more than Class B.

In the next session, Ye Lianping started from the first year of junior high school. Besides teaching Chinese, he engaged in many extracurricular activities. In some people’s words, he began to "do nothing".

He organized students to work part-time, took them all over the mountains to collect herbs, beat trees and fruits, and dragged them to the town to sell them on a scooter. He also asked students to raise rabbits, raise them and sell them, and also sold scrap metal. The money sold is used as class fees to buy books, stationery and sports equipment.

"How can you buy so many books when you don’t have much money to sell medicinal materials? There are not as many books in the whole school as in our class. " Chang Jiuming knows that Teacher Ye posted money.

He organized students to clean the toilet, picking up feces, which was dirty and tired. He took the lead and worked for three years. We also took students to clean the bridge, visit nursing homes, and visit military barracks.

Wang Xiaosi also worked as a teacher, but Ye Lianping did many things that he never thought of. "I think he is very close to the true meaning of education."

At that time, Ye Lianping disapproved of taking classes according to the textbook, and created his own "four-step teaching method", which was demonstrated and popularized in and outside the province. In the eyes of the students, Mr. Ye’s class is lively and interesting, like telling stories, and he is completely independent of textbooks.

The students said that Mr. Ye visited each student’s home at least once a year, no matter how far he went, running around the village with lanterns, and once he fell all over in mud. After understanding the situation, I especially take care of those students who have family difficulties and live far away, send money, send books and clothes, and invite them to eat and live in their own homes. When the students are admitted to the university, he personally sends them to report. Parents send two eggs, but he doesn’t want either.

Chang Jiuming’s classmates have to cross the river to go to school, and the river is 20 meters wide. Once it rained heavily and the water was rushing, they found a rope tied to their waist and crossed the river in a small basin. Teacher Ye was very moved when she saw them coming. She hugged them and said, "Children, you have worked hard." There are many similar little things, which makes Chang Jiuming feel that "he is different from any other teacher".

Integrity, benevolence and righteousness

In 1985, Ye Lianping was named "Excellent Teacher in the Province". Subsequently, he became a regular teacher from private schools, and Sheng Jinping, a member of wujiang town Party Committee, mobilized him to join the Party.

In 1985, Ye Lianping was named "Excellent Teacher in the Province".

During his three and a half years working in the embassy, he dealt with Americans all day, and he didn’t care about or understand politics. His life was almost smooth, except for He Fulin, an underground member of the Chinese Communist Party.

He Fulin moved from Shanghai Consulate General to Nanjing and became a colleague with Ye Lianping. In the winter of 1948, He’s identity was exposed and the Kuomintang surrounded the embassy. He finished the night shift that day and went to see Ye Lianping.

Ye Lianping recalled that at that time, he lived in the backyard of the embassy. He suddenly flashed in and said that he would spend the night, and his clothes were thin. He was not suspicious. He quickly added coal to make a fire and fried him a bowl of fried rice with eggs, but when he only ate eggs and could not swallow rice, he knew that he had something on his mind. Why did green gang bother him? Ye intentionally accompanied him home. Why refused? He said that he had sent his nephew He Gengfang to deliver letters to his wife in his coat and fur hat. They slept on their feet. Why did they toss and turn? Before dawn, they got up to go, hesitated for a moment and asked, "Xiaoye, do you have money?" Ye Lianping opened the box and gave him a stack of golden coupons, about twenty, each of which cost 20 thousand yuan. He put it in his pocket and walked out without counting. Ye Lianping pulled out a robe and told him to put on the cold, but the man had disappeared.

After He Fulin got away, his wife and children were monitored, and there were spies guarding the door all day long. When his wife returned to Shanghai, Ye Lianping personally escorted the mother and son to the railway station, followed by spies.

After liberation, He Fulin wrote to invite Ye Lianping to come to Shanghai. Ye Lianping went to his home (north of avenue joffre), where his wife knelt down with her two sons and thanked him for saving his life.

"Actually, I didn’t mean to save him. I didn’t know he was an underground party. It was accidental." Ye Lianping didn’t go to see him when he was in trouble.

After graduation, Zhang Guangyuan was transferred back to his hometown to work, and retired from the post of deputy mayor. Now he is the director of the town’s work committee, and he has been in contact with Ye Lianping, sometimes stunned by his words and deeds. In his view, Ye Lianping is a person with clear love and hate.

In the summer of 2012, Zhu Hongqing passed away. After Ye Lianping was expelled from the commune, he once lived in his house. Zhang Guangyuan, considering that Ye Lianping was old and the weather was hot and the road was far away, did not tell him and went to attend the funeral alone. After coming back, Ye Lianping got angry with him, and then rode to Yangzhou with two biscuits and a bottle of water, nearly 200 kilometers away. When I arrived at Zhujiajian, as soon as the car was released, I went straight to the graveyard to pay my respects without saying a word. I hurried back before dawn the next day, because I had to go to class, and the Zhujiajian couldn’t keep him.

At another funeral, Ye Lianping’s attitude was completely different.

The former village secretary, a student of Ye Lianping, was removed from his post and expelled from the Party for corruption and demolition funds. After his father died half a year later, Ye Lianping bought a wreath to attend the funeral, called him to the front and reprimanded him in public. The general idea was: How could you make such a mistake? You work hard, your father died, and there is still some glory. Just because you are a black sheep, you are greedy for a few money, and your father will die unsatisfied. A word, scold him in distress situation.

Ye Lianping thinks that he is also responsible for students’ misconduct, "indicating that education is not in place". Several cases of educational failure have made him more convinced that it is not a day’s work for teachers to cultivate people by virtue. "A teacher is worse if his words and deeds are inconsistent."

Yan Zheng, the second son of the old headmaster, was the first graduate of Ye Lianping and later became a private teacher. One day, I accidentally bumped into President Yan Zheng, who was punished for playing mahjong. Ye Lianping mediated from it, and it took a lot of effort. He couldn’t help but fire: "You are not qualified to educate him. You don’t want your children to play mahjong. Can you play it yourself?" The old headmaster fell silent.

Ye Lianping scolded the leaders of the Education Bureau because the counseling book he ordered was wrong. I offended the school director because I corrected a typo. His character is honest and frank, and he tends to treat things rather than people.

One noon in 1991, two teachers’ families were selling vegetables in the backyard of the school, and they had an argument and fought. The scene was ugly. Ye Lianping rushed over to pull them apart, and then ran to the then principal to solve it, but no one was seen everywhere. When he found it, he was eating and drinking at a teacher’s house. Ye Lianping got angry when he entered the door: "It’s all falling out outside, and you’re still drinking here!"

Ye Lianping had been overworked for two years at that time, and retired as soon as that semester was over.

a glutton for work

Ye Lianping held textbooks, reference books, and two erasers saved, and handed them over to the guidance office, so he couldn’t get out. "I cried on my desk." Many teachers don’t understand. What’s there to cry about after retirement?

He is also in such a sad mood when he dropped out of high school and left school. Teacher Lin, the head teacher, was very sad and sent a picture to say goodbye, which triggered his attachment to the teacher. After liberation, he saw that many bottom-level workers could not read, and their children could not read books, so he naturally devoted himself to literacy and opened nurseries. Later, he really engaged in education, realized the special responsibility of teachers to educate people, and decided to devote the rest of his life to it.

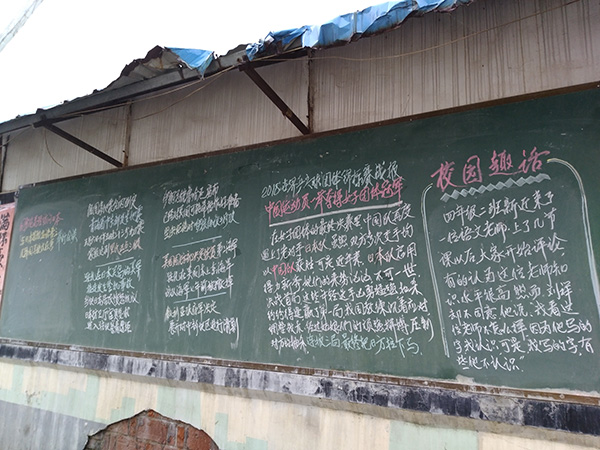

Ye Lianping is a restless person. During the period of being controlled in Nanjing, there was no occupation and no income. It is boring and painful to "eat all day long and have no intention", so he finds something for himself, cleans the streets every day, writes blackboard newspapers and makes up lessons for students. He still keeps the habit of writing blackboard newspaper.

Regardless of writing, speaking or writing a blackboard newspaper, Ye Lianping never made a draft, and he did it in one go, without any revision.

Ye Lianping watches the news every day so as to update the current events on the blackboard in the village.

After 28 years of retirement, he has not rested for almost a day. Every brigade primary school teacher asks for leave, and they all ask him to take his place, ranging from a few days to three years. If there is any need, just shout and go.

The substitute money is 300 yuan a month, and it is all returned to the school. He bought six accordions for five primary schools, installed electric lights for Songqiao Primary School, planted 100 Metasequoia trees for Longwang Primary School, and planted 220 poplar trees for Huangba Primary School.

After retirement, Ye Lianping took a class of students to Laoqiao Middle School, 30 kilometers away from Buchen, and took them to sweep the toilet for three years. This year’s students still remember him. They took him to Laoqiao for his birthday this Spring Festival, and gathered 28 students from all over the world.

Ye Lianping was very anxious to see that the poor English teaching conditions in rural schools affected her further studies. He was suspected to be a spy of the United States and Chiang Kai-shek before, and he never dared to speak English. At this time, he decided to "take it out and turn waste into treasure."

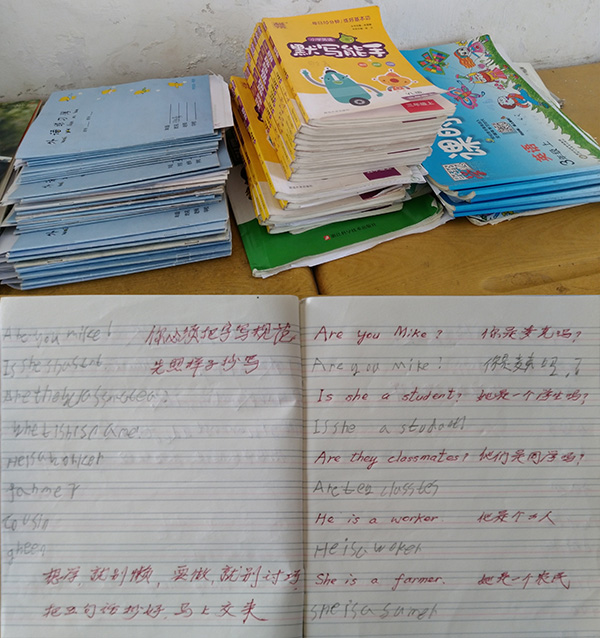

In 2000, he set up an English class in his home (later renamed as "staying in Children’s Home") and volunteered to tutor primary and junior high school students. He paid for all the books and utensils he needed. That 30-square-meter old house is packed with desks and children as soon as school is over every day.

These children come from neighboring villages, most of their parents are not at home, and their grandparents have no education and can’t help their homework. Six years ago, the town government paid money to turn his school warehouse across the hall into two classrooms, one for him to take classes and the other as a library, where students can do homework, read books, play chess and play ball.

Stay in the library in Children’s Home

Children’s Home, founded by Ye Lianping, has been promoted throughout the county.

Last year, in the senior high school entrance examination, Buchen School was admitted to 8 key high schools, and 5 of them made up lessons here. "Why do children have this enthusiasm? I don’t admit it because I don’t charge, and the key is effective. "

Some people called him 250, saying that he was putting on a show, while others hated him and cut off people’s money. "We have a primary school teacher here, who is my student. When he says it, he hits my own mouth. He makes up math for the children and charges 800 yuan a month."

Ye Lianping doesn’t care much about the criticism from the outside world. The prizes he has won are all filled with windows. For him, these awards are "disrespectful and shameful"; Only represents the past, not the future; Not a halo, but a burden.

"If I am a little wrong or even wrong in my manners, then this responsibility is not all mine, and the country will suffer. What will people say? As far as you are concerned, you are still a good person in China. "

This time, taking students to Hefei, Ye Lianping didn’t sleep well for two days. When the children got home safely, their hearts could be put down. "Although it is a good thing, if there is an accident, the reputation will be bad."

His wife didn’t understand him, and when he came back, he complained to him. He couldn’t bear to eat or wear, and he couldn’t bear to sit in a car with a dollar. He spent one or two thousand when he went to Hefei. The coal stove at home leaked and the seal was not tight. My wife went to buy a new one, and it was less than 20 yuan. Ye Lianping simply told her to return it. His principle is that the money that should be spent should never be stingy, and the money that should not be spent will not be spent at all.

Others say that a well-off life is a "well-off life". He feels that he is already well-off, has no worries about food and clothing, can go to the toilet at home, and has a toilet (note: a few years ago, the government helped him renovate and install a toilet). "I am very satisfied that I can survive climbing."

Ye Lianping’s wife is cooking. There is not a decent piece of furniture at home.

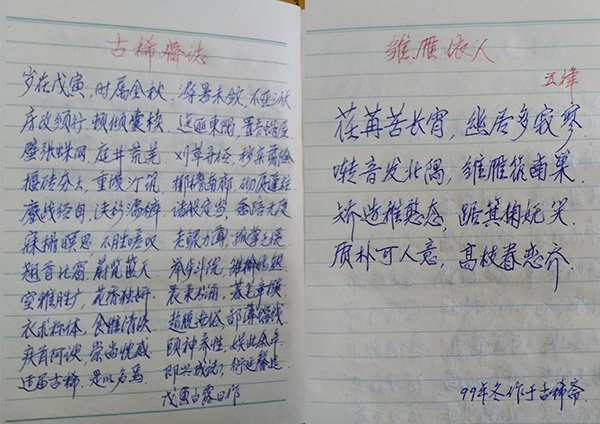

Ye Lianping occasionally writes poems. He calls his humble room "Gu Xi Zhai".

"die without ceasing"

Recently, several "key figures" have been wandering in Ye Lianping’s mind, worrying about their grades, further studies and economic situation, including an orphan who has been in Grade Two.

He still insists on home visits. Except for the new arrivals, every child who attends classes here has an account of his family situation, hobbies and shortcomings.

"Some people wonder that the old man is still riding a bike all over the sky, so I won’t fly, and the child will be given to you. If you can’t do it, how can you explain it?"

Five years ago, Ye Lianping was hit by a battery car on the way to his home visit. Since then, he has often fallen, becoming more and more serious. Once he fell to the ground in the middle of the night and was in a coma. President Ju sent him to Nanjing Hospital and found out that it was cerebral hemorrhage plus meningitis.

At first, the doctor said that he was too old to do anything. President Ju asked the doctor, saying that he was a good man in China, and now he is still giving free classes for the children, so the doctor is willing to have an operation. However, the risk is very high, and the success rate is only 5%. "It may not be possible to get off the operating table."

Maybe it’s a blessing. The operation was a success. I was supposed to be hospitalized for a month, but on the fourth day Ye Lianping was in a hurry to leave the hospital. The doctor couldn’t resist him, but he printed a certificate of voluntary early discharge for him to sign before he was willing to let him go.

At that time, my head was covered with gauze, and the thread had not been removed, so I couldn’t walk at all. He called President Ju first and asked if he could pick him up. President Ju advised him to have a good rest. He also called a student in Nanjing, a retired district-level cadre, and two cars arrived. The couple carried him on a stretcher and sent him home.

A week later, I went to Nanjing to have my stitches removed. The doctor said, "You old man, we have never seen you. You ran home in four days for such a big operation. What can you do when you go home?"

Not only is she distressed by the hospitalization expenses, but Ye Lianping also wants to go back to stay in Children’s Home early. Although she can’t attend classes, students come to borrow and return books every day. He sits there every day, borrowing books and writing memoirs.

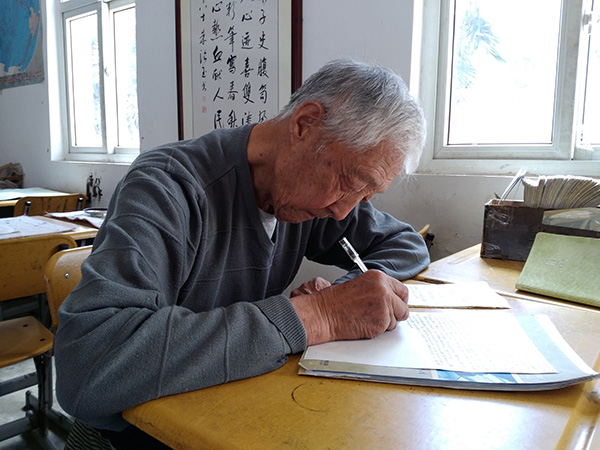

I didn’t have time to write before. I had classes for two days on weekends, changed my homework on Monday and Tuesday, printed handouts and took calligraphy classes on Wednesday, prepared lessons and made home visits on Thursday and Friday, and was busy all day.

Lao Han advised him not to be so tired anymore, and his body couldn’t stand it. He said, "Lao Han, just because I can’t, I don’t have time if I don’t do it again."

Having classes for two days every weekend, Ye Lianping spends 1-2 days correcting more than 80 assignments.

Ye Lianping was advised not to teach calligraphy for fear that he would be tired. Ye Lianping said: "I can’t hold back! How many of our teachers can’t pick up their brushes now? "

At that time, Wang Xiaosi asked him why he didn’t enjoy his retirement. He was all smiles: "I am already enjoying my happiness, and I am very happy. This kind of work is much better than rest! " Being with children all the time often makes him forget that he is an octogenarian.

For him, only by doing something can he be happy. He has a 16-character mind: life is endless and fighting is endless; Do your best and die. "I live one day, I jump one day, and I leave."

He has arranged things. If he walks in front of his wife, he will donate all his savings to Ye Lianping Scholarship Fund, except for a certain living expenses. This fund has been established for seven years, and he has continuously invested 50,000 yuan.

The second is to donate the remains to Anhui Medical University. He has five students studying at Anhui Medical University. When he visited during the New Year, he mentioned that there were no human specimens in anatomical experiments.

Ye Lianping has no descendants. His first wife was pregnant, because he was politically suspected, and she aborted the child and divorced him. Now this wife was taken in by him at the age of 71, when she was kicked out of the house by her son and daughter-in-law, and her living environment was in a mess.

Ye Lianping didn’t have much communication with his wife, and their hearing was not very good. The students said that grandparents quarreled occasionally, but they couldn’t hear each other and said their own things.

Although there are no children or daughters, it is another comfort to have a full house of students and a world of peaches and plums. At present, his biggest regret is that he can’t find a successor. "After I leave, who will take care of these children?"

At present, the students boarding at Ye Lianping’s home are poor families. Their home is far from school and there is no electricity. Since the first day of junior high school, the senior high school entrance examination is about to take place. Her homework is not very good. Ye Lianping promised her that no matter whether she does well or not, she should not worry about economic problems. "As long as Grandpa has a breath, you won’t be unable to afford to study." She wants to be a teacher in the future and change the current situation of rural education. "I hope to create talents like Teacher Ye."

Spring goes to Qiu Lai, the sun rises and the moon sets, and children gather here from all over the world, studying, frolicking, running and growing, and scattered all over the world. Ye Lianping is like a scarecrow. The wind can’t blow down and the thunder can’t move. He will guard this country, this classroom and these children until the end of his life.

"Goodbye, Teacher Ye!" The children always say.

After school, the children came to stay in Children’s Home and asked about their homework around Teacher Ye.

The chairman of the county Federation of Literary and Art Circles said that he was a "candle that never goes out", but he disagreed. "Am I so bright? The evaluation I gave myself was at best a firefly. "

Notice on printing and distributing guidelines for risk assessment of scientific experiments

Notice on printing and distributing guidelines for risk assessment of scientific experiments